Innovation In Sustainability

The challenges we face today go beyond how we produce new products and materials. The heart of the issue lies with the useful lifecycle of the materials we use and the products we produce. We proudly feature our NEW Comfortek ECO Plus. Helping reduce the waste impact on our environment for a better tomorrow, while providing the ultimate in comfort today.

Our Commitment to Health & Sustainability

At ErgoGenesis, manufacturer of BodyBilt products, we are committed to creating healthier work environments in two distinct but equally important ways. First, we manufacture ergonomic workplace products that support the safety and health of workers in every type of work environment. Second, those products are created using environmentally-friendly or “green materials” and environmentally-responsible processes.

With our dedication to these two goals, ergonomics and productivity work together with environmental integrity to support healthy and sustainability within our team, for our customers, for the world in general, and for the generations to come.

Our Sustainability Practices

Our processes and products at ErgoGenesis/BodyBilt contribute to sustainability and reduce environmental footprints in the following ways:

Long-Life Products

Durability and quality of design ensure a long life cycle for BodyBilt seating and our other ergonomic products for the workspace. Engineered for sustainability, BodyBilt products are less-frequently replaced, resulting in not only cost savings for our customers as well as sound environmental stewardship.

Modular Construction

Our modular approach provides more than the convenience of customizing your BodyBilt solution to meet your specific needs. It also means less waste, as individual parts can be replaced as the needs of your employees change or as parts are damaged – rather then replacing the entire chair.

Recycled Materials

We are focused on sourcing and manufacturing with more environmentally-friendly materials and components. As such, we use pre/post-consumer recycled materials in the construction of our chairs – including steel, aluminum, and fabric. In addition, our products are made with 90% recyclable content.

Soy-Based Foam

ErgoGenesis pioneered the use of BioFlex™ Hybrid Foam made from soy products for seating materials. Compared to petroleum-based solutions, this bio-foam lessens dependence on fossil fuels and foreign oil, leaving a smaller environmental footprint. BioFlex Hybrid Foam is also manufactured without harmful CFSs.

Blanket-Wrap Ship

We also offer our customers the option of using blanket-wrapped shipping in place of the standard boxes. Chairs are placed in a plastic bag and individually wrapped in blankets for protection. This practice not only reduces cardboard and boxing waste, but also increases our shipping capacity by 65%, reducing emissions.

Long-Life Products

Durability and quality of design ensure a long life cycle for BodyBilt seating and our other ergonomic products for the workspace. Engineered for sustainability, BodyBilt products are less-frequently replaced, resulting in not only cost savings for our customers as well as sound environmental stewardship.

Modular Construction

Our modular approach provides more than the convenience of customizing your BodyBilt solution to meet your specific needs. It also means less waste, as individual parts can be replaced as the needs of your employees change or as parts are damaged – rather then replacing the entire chair.

Recycled Materials

We are focused on sourcing and manufacturing with more environmentally-friendly materials and components. As such, we use pre/post-consumer recycled materials in the construction of our chairs – including steel, aluminum, and fabric. In addition, our products are made with 90% recyclable content.

Soy-Based Foam

ErgoGenesis pioneered the use of BioFlex™ Hybrid Foam made from soy products for seating materials. Compared to petroleum-based solutions, this bio-foam lessens dependence on fossil fuels and foreign oil, leaving a smaller environmental footprint. BioFlex Hybrid Foam is also manufactured without harmful CFSs.

Blanket-Wrap Ship

We also offer our customers the option of using blanket-wrapped shipping in place of the standard boxes. Chairs are placed in a plastic bag and individually wrapped in blankets for protection. This practice not only reduces cardboard and boxing waste, but also increases our shipping capacity by 65%, reducing emissions.

Third-Party Sustainability Certifications

As evidence of our commitment to the environment and healthier workplaces, ErgoGenesis/BodyBilt has tested and received certifications for the following standards:

MAS Certified Green

Materials Analytical Services, LLC has recognized and awarded ErgoGenesis, LLC as being in compliance with the following standards:

- Dynamic Chamber Emissions Testing Certificate of Compliance with ANSI/BIFMA X7.1

- MAS Low VOC Emitting Furniture/ANSI/BIFMA e3 Sections 7.6.1, 7.6.2, and 7.6.3

- MAS Low VOC Emitting Furniture/Collaborative for High-Performance Schools (CHPS)

- MAS Low VOC Emitting Furniture/California Dept. of Public Health (C-DPH) Standard

MAS Certified Green

The GREENGUARD Certification Program (formerly known as GREENGUARD Indoor Air Quality Certification) gives assurance that products designed for use in indoor spaces meet strict chemical emissions limits, which contribute to the creation of healthier interiors.

LEED Credits

Depending on the particular project, BodyBilt chairs can offer up to 8 LEED Credit Points. These possible LEED Credits include:

- 2.1 – Construction Waste Management – Divert 50% From Landfill

- 2.2 – Construction Waste Management – Divert 74% From Landfill

- 3.3 – Resource Reuse – 30% Furniture and Furnishings

- 4.1 – Recycled Content – 10% (Post-consumer and 1/2 Pre-consumer)

- 4.2 – Recycled Content – 20% (Post-consumer and 1/2 Pre-consumer)

- 5.0 – Regional Materials – 10% Manufactured Regionally

- 5.1 – Regional Materials – 20% Manufactured Regionally

- 6.0 – Rapidly Renewable Materials

- 4.5 – Low-Emitting Materials – Systems Furniture & Seating

duvaltex

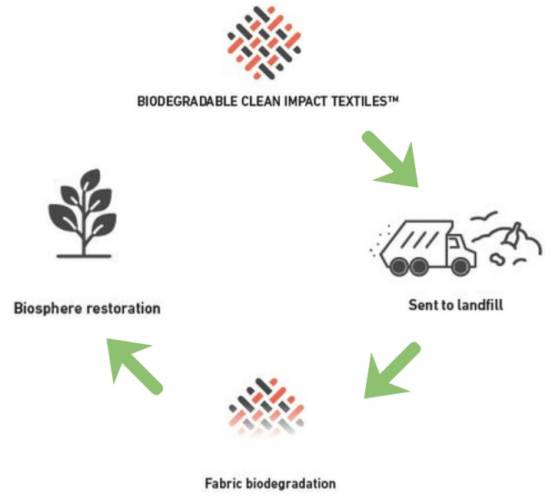

*Rate and extent of biodegradation into elements found in nature is 91% after 1,278 days under ASTM D5511 (Anaerobic Biodegradation of Plastic Materials Under High Solids Anaerobic Digestion Conditions). The test was done with the same component (PET) polyester and biocatalyst additive. No evidence of further degradation. Not applicable to CA, WA, MD.

Design without compromise

Industry-First 100% Post-Consumer Recycled

Biodegradable* Polyster. Help keep plastic out of landfills with biodegradable* CLEAN IMPACT TEXTILES® Polyester Fabrics. Redesigns thrown-away materials and transforms them into revolutionary biodegradable* textiles – contributing to the circular economy and preserving our planet for future generations.

- Biodegradable* in landfill after 1,278 days (tested under ASTM D5511)

- Back to biosphere as fast as natural wool fabric

- Designed and manufactured for recyclability

- Made with sustainable manufacturing practices

- Meets or exceeds all ACT performance guidelines

- NSF/ANSI 336 – sustainability assessment for commercial furnishings fabric, and carries the FACTS Gold Certification Mark

- Full-color capabilities & novelty yarns

- Could contribute to LEED points for recycled content and materials and resources